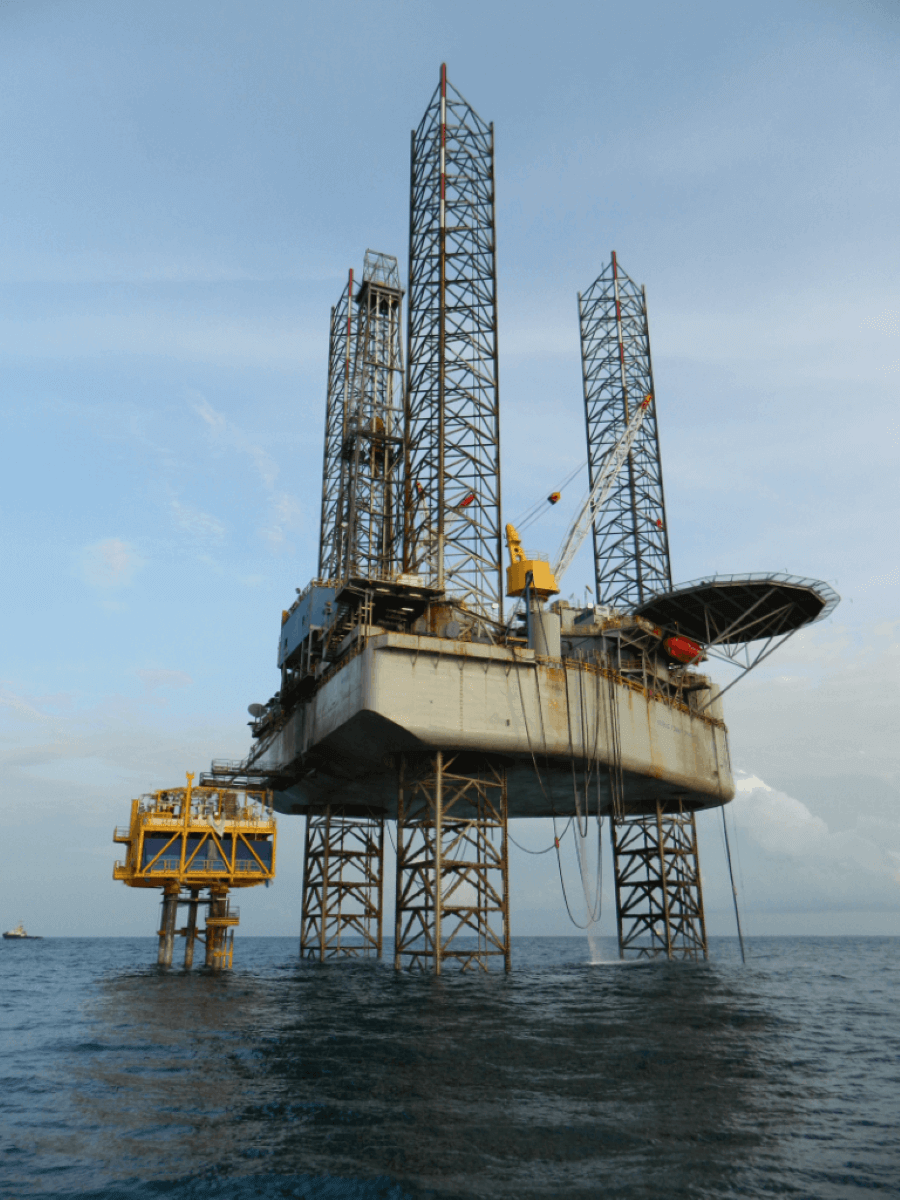

The only way is jack-up rigs: cost effective solutions

As we learned in the first installment of this two-part series, jack-up rigs could become more common place than their well-loved, floating cousin, the semi-submersible (semi-sub). In this second and final blog, we’ll explore examples of where jack-ups rigs might be a more cost-effective and efficient choice.

Opting for the right choice of rig infrastructure for exploration, development, intervention and decommissioning on subsea wells is more difficult than ever. Decision making models are becoming increasingly complex as front-end considerations now include aging infrastructure as well as extensive subsea architecture, ultra-deep drilling and cost.

Riding the waves

A major advantage of a jack-up rig is its ability to withstand bad weather or poor conditions once fixed on a location. Because it has a surface BOP with a subsea riser system, and because it is fixed above the wells, the offset of waves and vessel responses is very low. So, any tension or stresses on the riser system, subsea and surface equipment is also going to be much lower than that of a semi-sub. In fact, jack-up rigs with subsea high-pressure riser systems can be used, without interruption, in conditions exceeding 50-year extreme storms, and waves over 30 metres.

But a semi-sub can only handle wave heights of around 2-3 metres before it will have to stop operations completely and potentially unlatch or move off well centre. This creates considerable operational downtime when working in shallow water environments, where impacts are magnified – increasing rig rental time and costs.

Subsea assessment

In areas like the UKCS, where operations have taken place over decades and extended incrementally, there needs to be enough space for the jack-up rig to place its legs on the seabed. It’s important the sea floor can take the weight of the legs, which sounds dramatic, but the legs can break through and create instabilities if it can’t bear the load. This is something that is easily assessed via riser or conductor analysis services.

Both jack-up rigs and semi-subs will transfer motion to the subsea well. However, the motion of a semi-sub, even during calm wave conditions, can significantly reduce the fatigue lifetime and exceed allowable operating parameters of critical subsea well equipment, including the wellhead housing welds. A jack-up rig, with a high-pressure riser system, can provide a more environmentally stable solution that can reduce fatigue damage from drilling, and withstand combined well control, 50-year storm and tension failure events.

Money matters

Environmental considerations aren’t the only factor, money matters too. According to WoodMac reports, in 2019, the average global blended cost of a mid-water floater is around $223,000 USD per day (p/d). In the next few years, operators will be looking at a sizeable investment with predictions of over $310,000 USD p/d by 2023.

However, if you can use a jack-up rig for the same application, at 2019 rates the average global blended cost would be just $136,000 USD p/d — an $87,000 daily saving.

Apply this methodology to the number of development wells forecast over the next five years and the industry would make savings of more than $3.2 billion.

So, although rental and setup costs of a jack-up rig are much less than semi-sub rigs, the advantages go beyond cost. With the right equipment partner, it is easier than ever to manage the interfaces between the seabed and the surface, and ensure that the engineering expertise and management is in place for a safe and efficient operation.

Contact us to find out more about how our advanced jack-up rig drilling products and solutions could help on your next project.